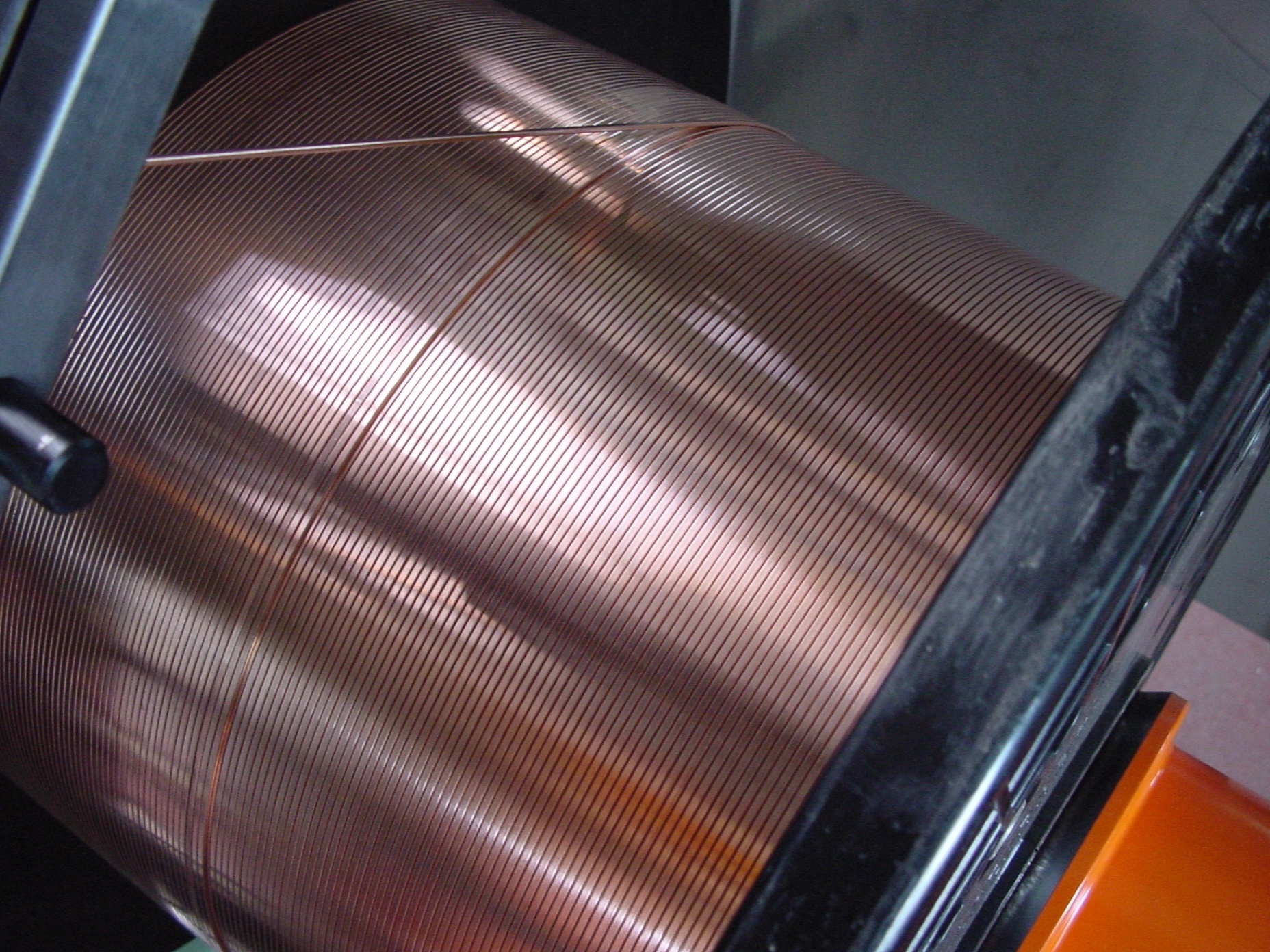

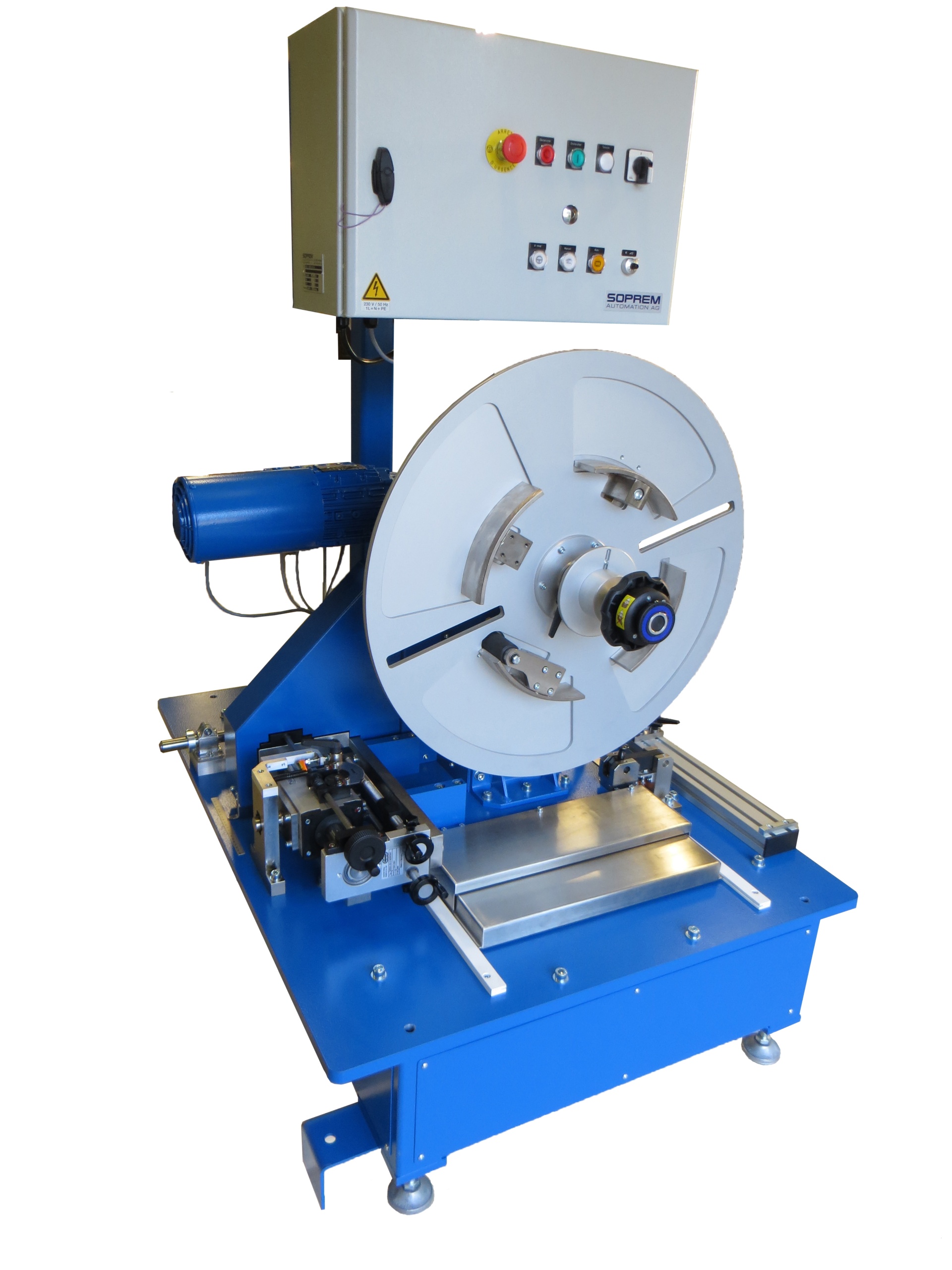

Positioning units – VU / VE

Functions (technical details)

Mechanical or electronic positioning units to wind thin, narrow strips or wire onto carrier spools.

Positioning units and decoilers can be combined to meet your needs.

- Mechanical rolling ring gears positioners. Positioning step and reverse position adjustable with mechanical stops.

- Electronic positioners with fully automated touchscreen control, with setting options for the precise positioning of several layers of materials.

- Programming options for positioning steps, coil edges and programme management.

- Positioning units and decoilers can be combined to meet your needs.

Options

We would be more than happy to assist you and help make your specific implementation requests a reality. Simply ask one of our specialists. We can meet the following requirements, among others:

- Decoilers with various load weights

- Various coil bases

- Length measurements

- Strip or wire feed systems

Strip extractor – MA

-

Torque controlled strip extractor

-

strip extractor can be combined with other components depending on requirements (e.g.: in combination with conventional decoilers or passive straightening devices)

Torque controlled strip extractor

strip extractor can be combined with other components depending on requirements (e.g.: in combination with conventional decoilers or passive straightening devices)

| Size 50 | |

| Roller Ø | 50 mm |

| Max. strip width | 550 mm |

| Strip thickness | 0.1 – 2 mm |

Functions (technical details)

- Powered by electric motor with anti-backlash gears

- Feed length measurement via incremental measurement sensor on motor

- Pneumatic intermediate lifting

- Adjustable contact force of rollers

Options

We would be more than happy to assist you and help make your specific implementation requests a reality. Simply ask one of our specialists. We can meet the following requirements, among others:

- Various surface treatments of rollers

- Adjustable lateral strip guides

- External length measurement system via measuring roller and sensor

- Strip material finish monitoring

- Various strip feed systems

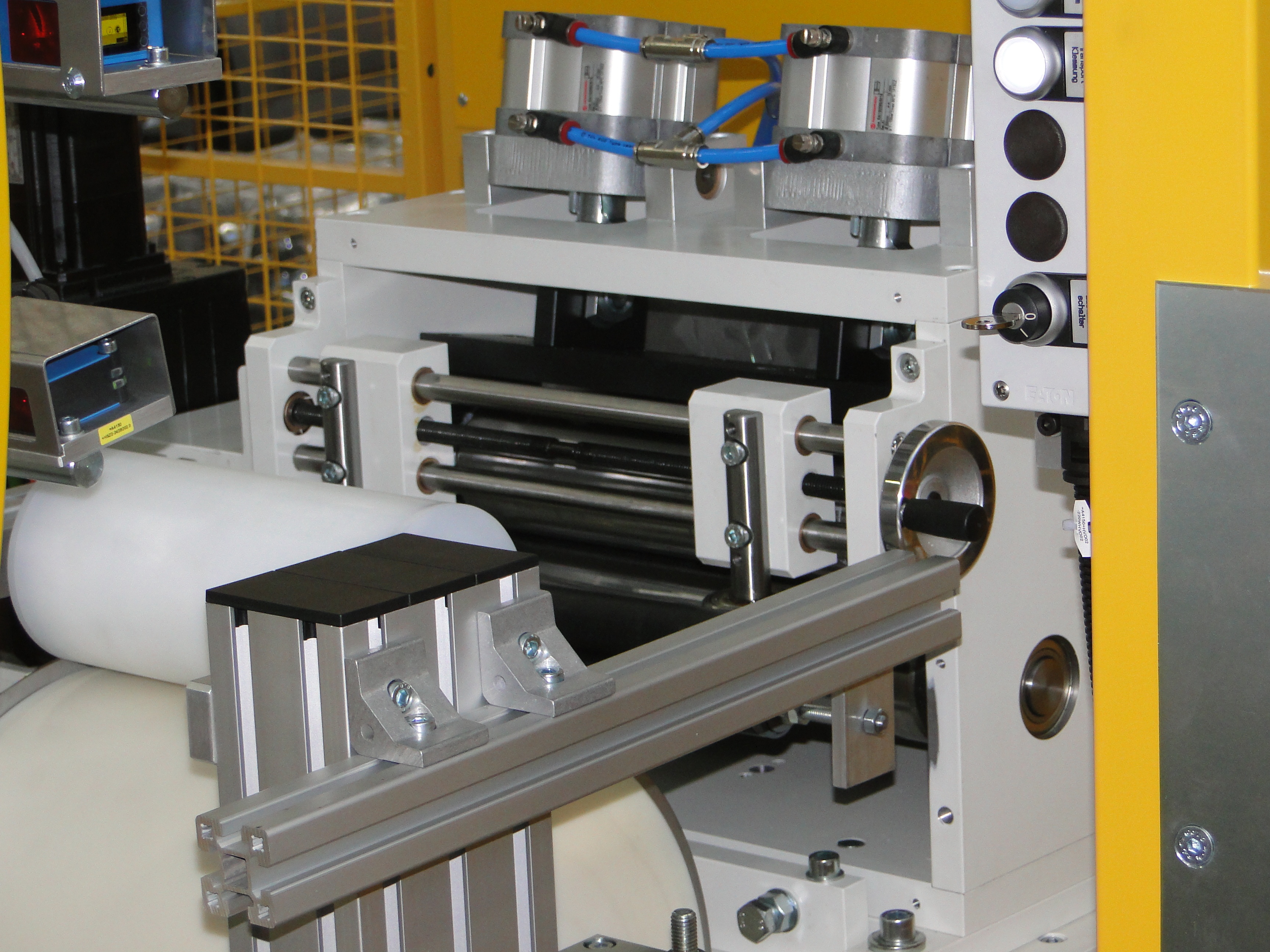

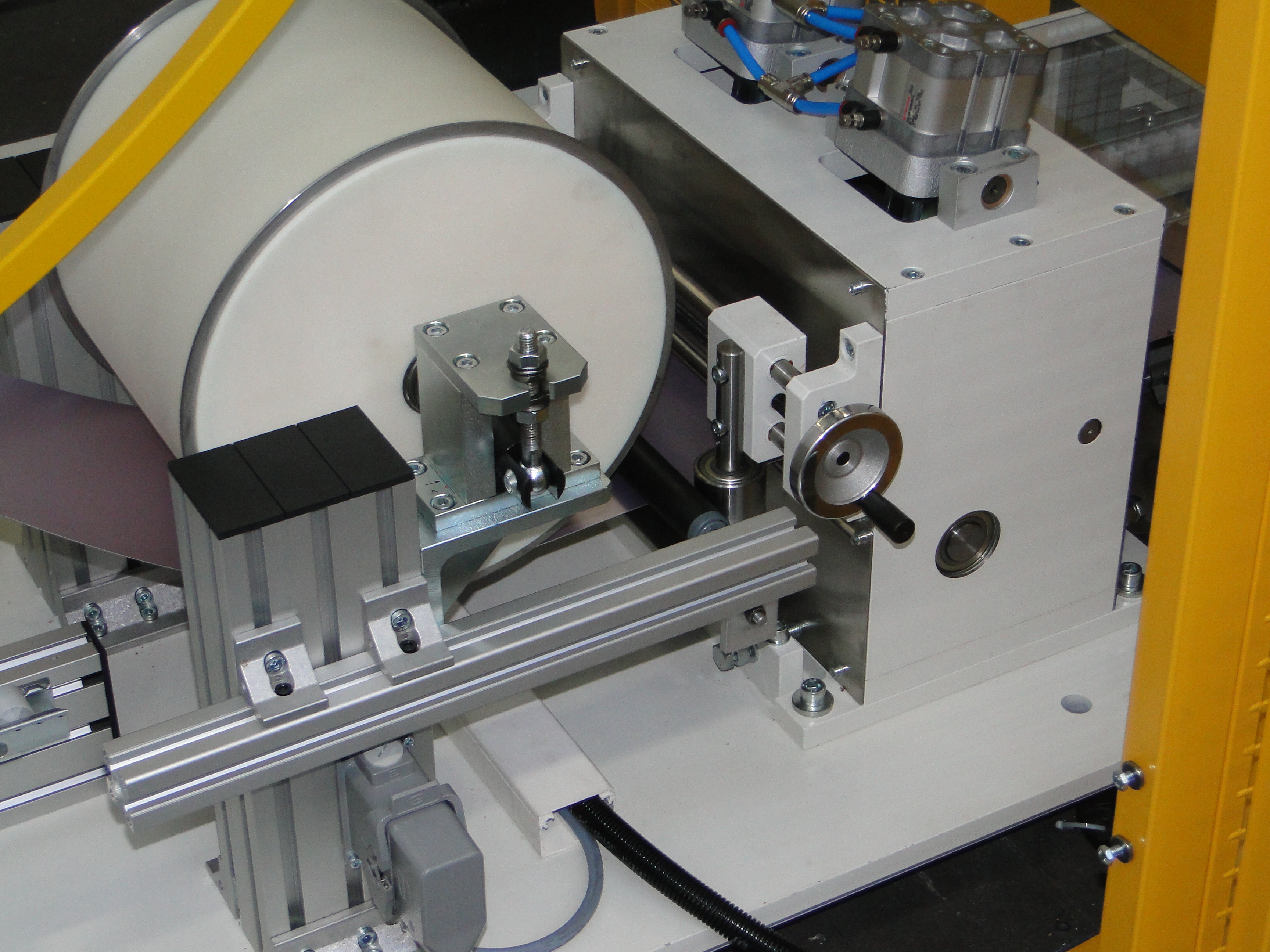

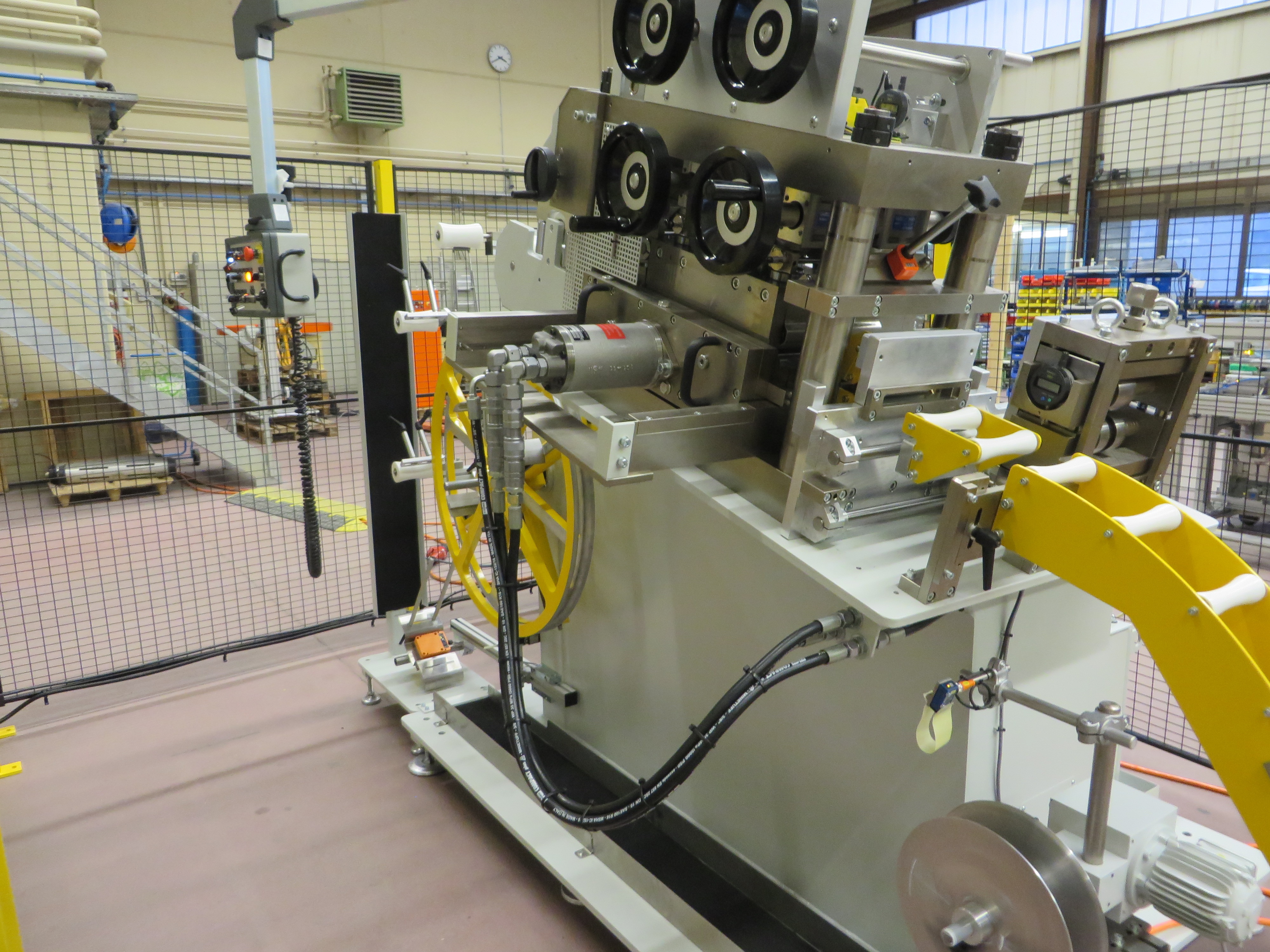

Roller feeder – WV

-

Suitable for timed feed of strip material

-

Modern axis control with programme management

-

Simple and quick operation controls result in short changeover time

-

Roller feeders can be combined with other components depending on requirements (e.g.: in combination with conventional decoilers, straighteners or strip feeding lines)

Suitable for timed feed of strip material

Modern axis control with programme management

Simple and quick operation controls result in short changeover time

Roller feeders can be combined with other components depending on requirements (e.g.: in combination with conventional decoilers, straighteners or strip feeding lines)

| Size 50 | Size 80 | Size 100 | |

| Roller Ø | 60 mm | 80 mm | 100 mm |

| Max. strip width | 300 mm | 800 mm | 1000 mm |

| Strip thickness | 0.1 – 2 mm | 0.2 – 3 mm | 0.2 – 6 mm |

| Max. speed | 100 m/min | 150 m/min | 120 m/min |

| Max. stroke rate | 200 | 300 | 300 |

Functions (technical details)

- Powered by electric motor with anti-backlash gears

- Feed length measurement via incremental measurement sensor on motor with strip end sensor

- Electropneumatic interim lifting with adjustable roller opening

- Adjustable contact pressure of rollers

- Adjustable lateral strip guides and roller basket at infeed

Options

We would be more than happy to assist you and help make your specific implementation requests a reality. Simply ask one of our specialists. We can meet the following requirements, among others:

- Various surface treatments of rollers

- External length measurement system via measuring roller and feeder

- Mountable to press, manual or motorised height adjustment

- Symmetrically adjustable lateral strip guides, manual or motorised

- Various strip feed systems

Straightener for sabre-shaped strips – SBR

-

Passive straightener to correct sabre-shaped deformations in strip material

-

Straightener can be combined with other components depending on requirements (e.g.: in combination with conventional straighteners or strip feeding units)

Passive straightener to correct sabre-shaped deformations in strip material

Straightener can be combined with other components depending on requirements (e.g.: in combination with conventional straighteners or strip feeding units)

| Size 7/6/27 | Size 7/15/36 | Size 7/30/45 | Size 7/50/70 | |

| Straightening rollers Ø | 7 x 27 mm rollers | 7 x 36 mm rollers | 7 x 45 mm rollers | 7 x 70 mm rollers |

| Strip width | 3 – 6 mm | 3 – 15 mm | 5 – 30 mm | 15 – 50 mm |

| Max. strip thickness | 1 mm | 1,5 mm | 3 mm | 5 mm |

| Width/thickness ratio | 1:10 | 1:10 | 1:10 | 1:10 |

Functions (technical details)

Size SBR/7/6/27

- Individual adjustment of straightening rollers using micrometre spindles

- Read setting depth on scale of micrometre

- Straightening rollers with puncture for the respective strip thickness

- All exposed parts nickel-plated

Size SBR/7/15/36, SBR/7/30/45 and SBR/7/50/70

- Individual adjustment of straightening rollers using mandrels and socket wrench

- Depth setting read via a mechanical decimal counter

- Strip thickness can be set on each straightening roller using a double lock nut assembly

- Quick access to the three feed rollers

- All exposed parts nickel-plated

Options

We would be more than happy to assist you and help make your specific implementation requests a reality. Simply ask one of our specialists. We can meet the following requirements, among others:

- Pre-straightening devices to flatten coil deformation

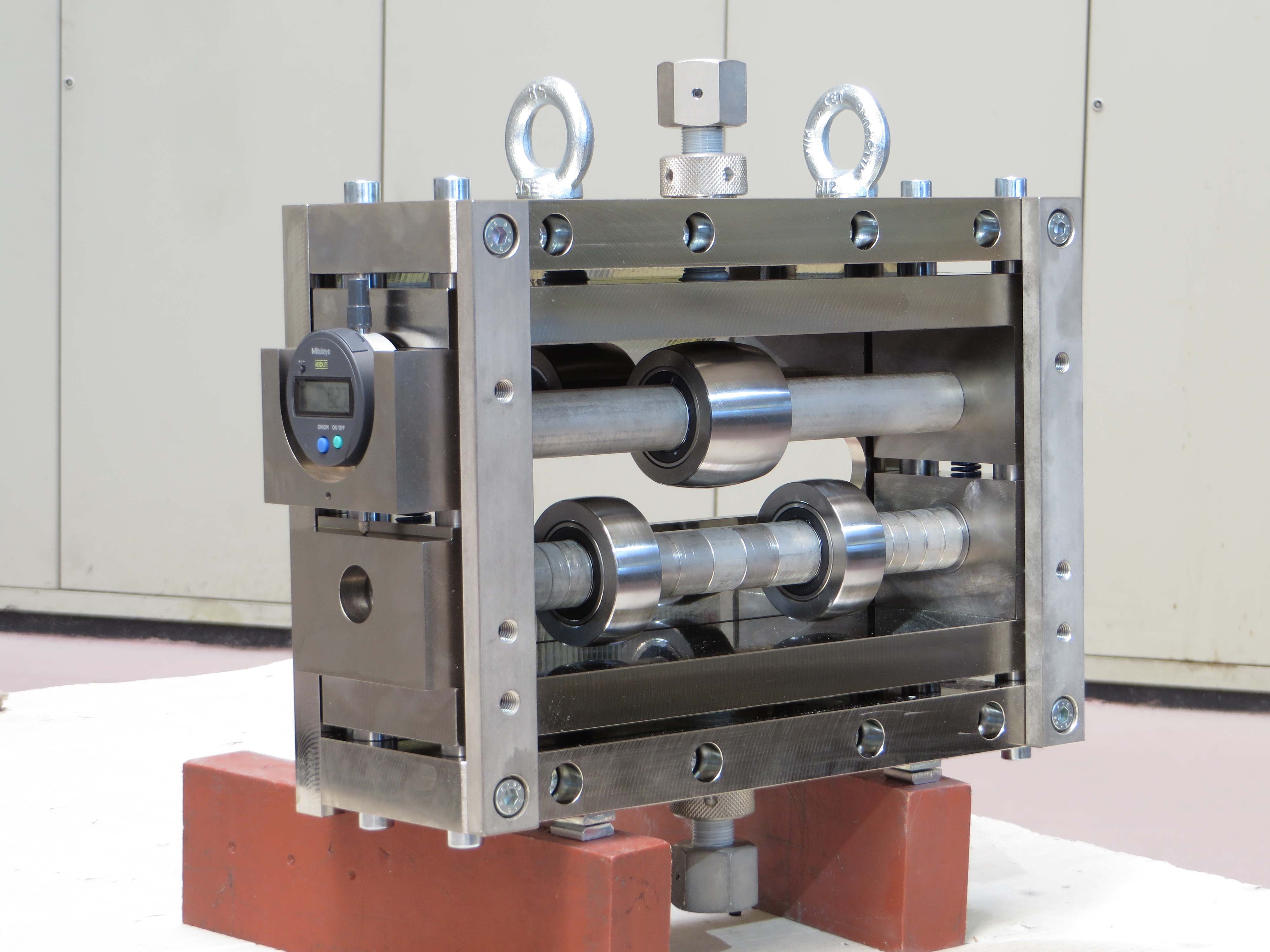

Bending device for cross bow deformation – BV

-

Straightening unit to straighten strip material with cross bow deformation

-

Bending devices can be combined with other components depending on requirements (e.g.: in combination with conventional straighteners or strip feeding units)

Straightening unit to straighten strip material with cross bow deformation

Bending devices can be combined with other components depending on requirements (e.g.: in combination with conventional straighteners or strip feeding units)

| Size 32 | Size 68 | Size 120 | |

| Straightening rollers Ø | 32 mm | 68 mm | 120 mm |

| Max. strip width | 100 mm | 300 mm | 420 mm |

| Strip thickness | 0,1 – 1,5 mm | 1,5 – 3 mm | 3 – 6 mm |

Functions (technical details)

- Three hardened and polished straightening rollers

- Upper straightening rollers individually adjustable for height

- Setting height displayed via a digital dial gauge

- Width between straightener rollers can be set using spacer sleeves

Options

We would be more than happy to assist you and help make your specific implementation requests a reality. Simply ask one of our specialists. We can meet the following requirements, among others:

- Lateral strip guides can be set individually for width

- Assembled onto straightener with sliding mechanism

Strip cleaning unit – BRE

-

Autonomous cleaning unit for strip material to remove residue such as shavings and dust.

-

Cleaning system with two rotating brushes and a vacuum unit to connect to an industrial vacuum.

-

Unit can be tilted for optimum cleaning.

-

Rotating pair of brushes with dust scraper and adjustable speed.

-

Strip cleaning machines can be combined with other components to meet requirements (e.g.: positioned before strip straighteners or feed units).

Autonomous cleaning unit for strip material to remove residue such as shavings and dust.

Cleaning system with two rotating brushes and a vacuum unit to connect to an industrial vacuum.

Unit can be tilted for optimum cleaning.

Rotating pair of brushes with dust scraper and adjustable speed.

Strip cleaning machines can be combined with other components to meet requirements (e.g.: positioned before strip straighteners or feed units).

| Strip cleaning unit | |

| Max. brush speed | 700 min-1 |

| Max. strip width | 160 mm |

| Max. strip thickness | 2,5 mm |

Functions (technical details)

- Solid metal construction with stainless-steel finish

- Removable base serves as dirt collector.

- Vacuum connector hose Ø 50 mm

- Weight 15 kg

Options

We would be more than happy to assist you and help make your specific implementation requests a reality. Simply ask one of our specialists. We can meet the following requirements, among others:

- Available in special sizes on request.

- Attachment supports for existing systems.

- Height of upper brush can be adjusted by means of a handle for strip thicknesses up to 6 mm.

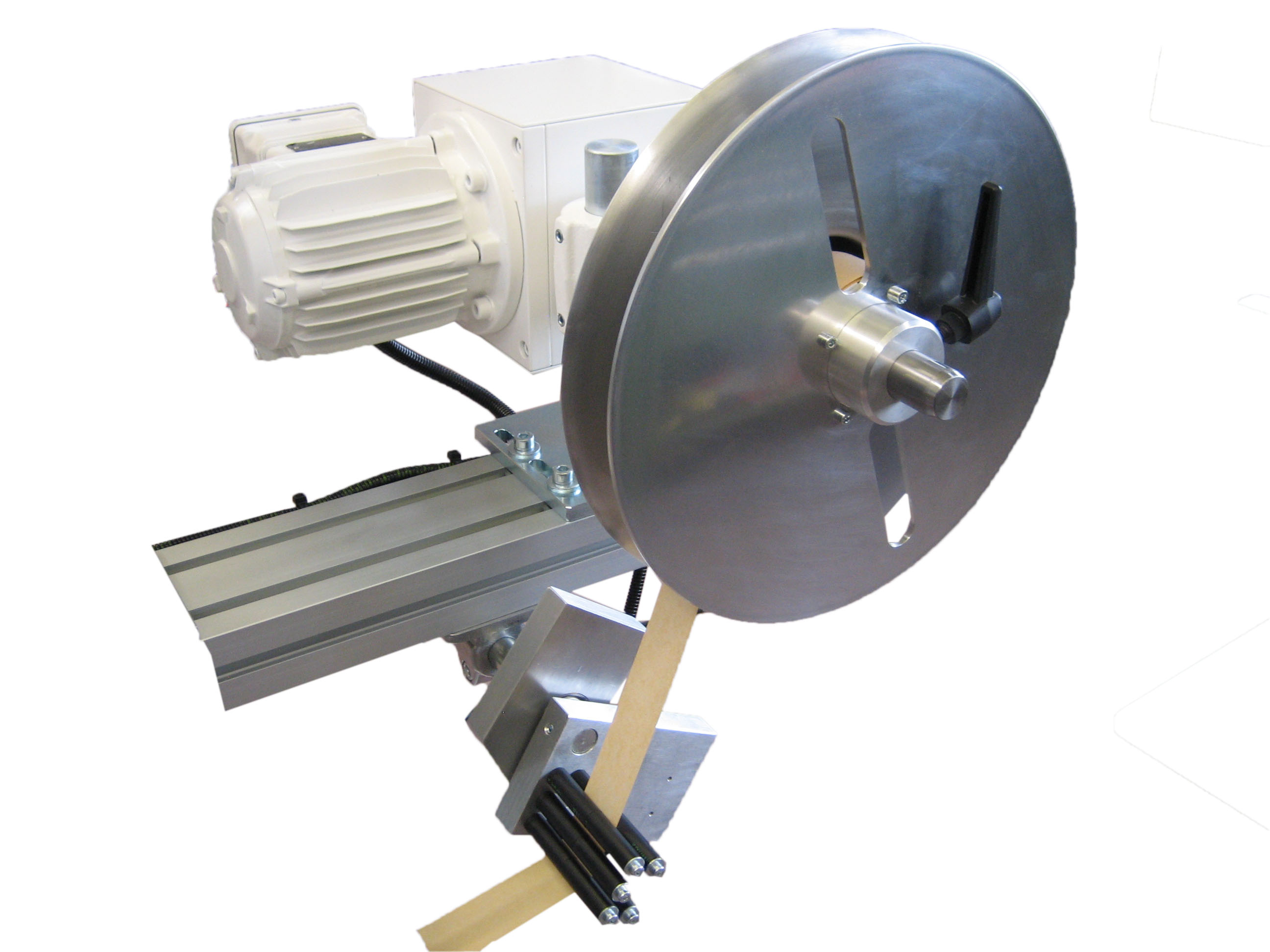

Winder for interlayer materials – EW / EB

-

Winder to coil / rewind interlayer materials, to be mounted onto a strip decoiler.

Winder to coil / rewind interlayer materials, to be mounted onto a strip decoiler.

| Winder for interlayer materials | |

| Max. loading weight | 15 kg |

| Max. strip width | 80 mm |

| Adjustable torque | 12 – 180 Ncm |

| RPM | 2 – 140 min-1 |

Functions (technical details)

Motorised interlayer material winder

- Tensile force controlled power using an induction motor

- Adjustable tensile force

- Automatically adjusting RPM

Interlayer material winder with brake system

- Decoiling system for interlayer material with friction brake

- Adjustable braking power

Options

We would be more than happy to assist you and help make your specific implementation requests a reality. Simply ask one of our specialists. We can meet the following requirements, among others:

- Available in special sizes on request

- Special infeeder bases for interlayer material

- Control system for monitoring presence of interlayer materials

+41 32 644 35 35

+41 32 644 35 35