INDUSTRIES

For years, SOPREM has been a partner you can depend on. We automate complex processes for the following industries:

Watch industry I Furniture industry I Communications industry I Medical industry I Automotive industry I Bicycle industry I Airplane industry I Construction industry

News

SOPREM always on the move

Recent SOPREM customer projects

Decoiler-Straightener

Highest straightening quality meets the most modern control technology

- Precision straightener with 19 straightening rolls Ø 35 mm

for strip thickness up to 4,2 mm and strip width up to 450 mm - Motorized height adjustment of upper rocker, operating by touch panel

- Contactless loop control station by laser sensor for continuous speed control of straightener

- Safety protective cover for the straightener

- Hydraulic strip introduction assistance system and hydraulic folding strip conveying table for facilitated setup operation

- Braked double decoiler with loading weight 3000 kg each side

- Automatic revolving base, rotation powered by hydraulic motor

- Hydraulic coil loading car for automatic loading of the coil onto the decoiler

Retrofit Decoiler-Straightener-Feeder-Installation

After more than 15 years of daily, partly multi-shift operation, the time has come for a complete machine refurbishment.

- The straightening head mechanics were equipped with new gears, bearings and seals. In addition, all parts in direct contact with the material, such as straightening and transport rolls, were replaced

- The drive technology, servo motors, encoders and gears, were upgraded to the latest state of the art technology

- The complete machine control system was modernized and integrated into a touch panel

Due to the modernized servo technology, the customer now has a higher parts output per minute with enhanced repeat accuracy.

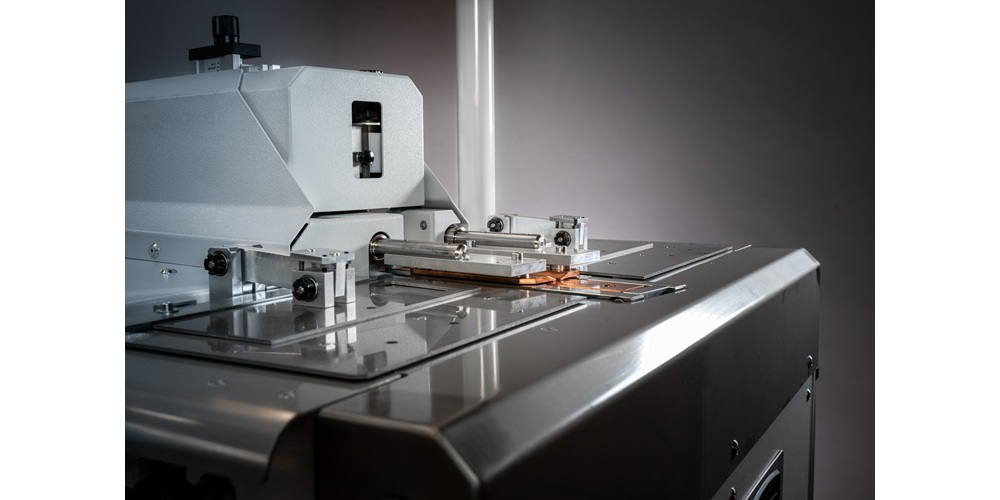

Decoiler-Straightener

- Straightener with 7 straightening rolls Ø 50 mm

for strip thickness up to 2 mm and strip width up to 800 mm - Contactless loop control station for continuous speed control of straightener

- Hydraulic strip introduction assistance system and hydraulic folding strip conveying table for facilitated setup operation

- Braked decoiler with loading weight 5500 kg

with hydraulic auxiliary motor for mandrel positioning and easy strip introduction - Hydraulic coil loading car for automatic loading of the coil onto the decoiler

Testimonials

Reactions from our customers

“WKK as service provider in the stamping industry is reliant upon a state-of-the-art and dependable manufacturing process. We appreciate SOPREM for it’s quality, outstanding customer service as well as it’s competent customer adivsory services”

“SOPREM is an experienced partner and collaboration with them is professional and goal-oriented”

“As long-standing client of SOPREM we appreciate their tailor-made products and their excellent and reliable personal service”

+41 32 644 35 35

+41 32 644 35 35

“WKK as service provider in the stamping industry is reliant upon a state-of-the-art and dependable manufacturing process. We appreciate SOPREM for it’s quality, outstanding customer service as well as it’s competent customer adivsory services”

“WKK as service provider in the stamping industry is reliant upon a state-of-the-art and dependable manufacturing process. We appreciate SOPREM for it’s quality, outstanding customer service as well as it’s competent customer adivsory services” “SOPREM is an experienced partner and collaboration with them is professional and goal-oriented”

“SOPREM is an experienced partner and collaboration with them is professional and goal-oriented” “As long-standing client of SOPREM we appreciate their tailor-made products and their excellent and reliable personal service”

“As long-standing client of SOPREM we appreciate their tailor-made products and their excellent and reliable personal service”