Strip straighteners

| Precision straightening | Moderate straightening | Rough straightening | |

|---|---|---|---|

| Number of straightening rollers | 19 | 9 / 11 | 5 / 7 |

| Straightening roller Ø | 6 – 35 mm | 25 – 90 mm | 40 – 100 mm |

| Thickness range | 0,05 – 6 mm | 0,1 – 8 mm | 0,1 – 9 mm |

| Max. passage width | 450 mm | 1300 mm | 1300 mm |

Functions (technical details)

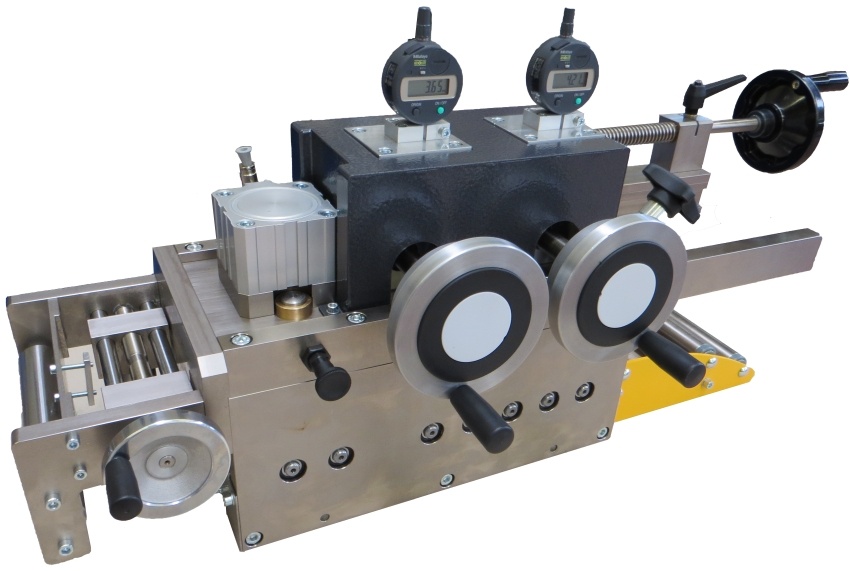

- Variable speed control

- Straightening depth display

- Pneumatic feed rollers

- Centrally adjustable lateral guide rollers at the straightener infeed

- Roller cage at the straightener outfeed

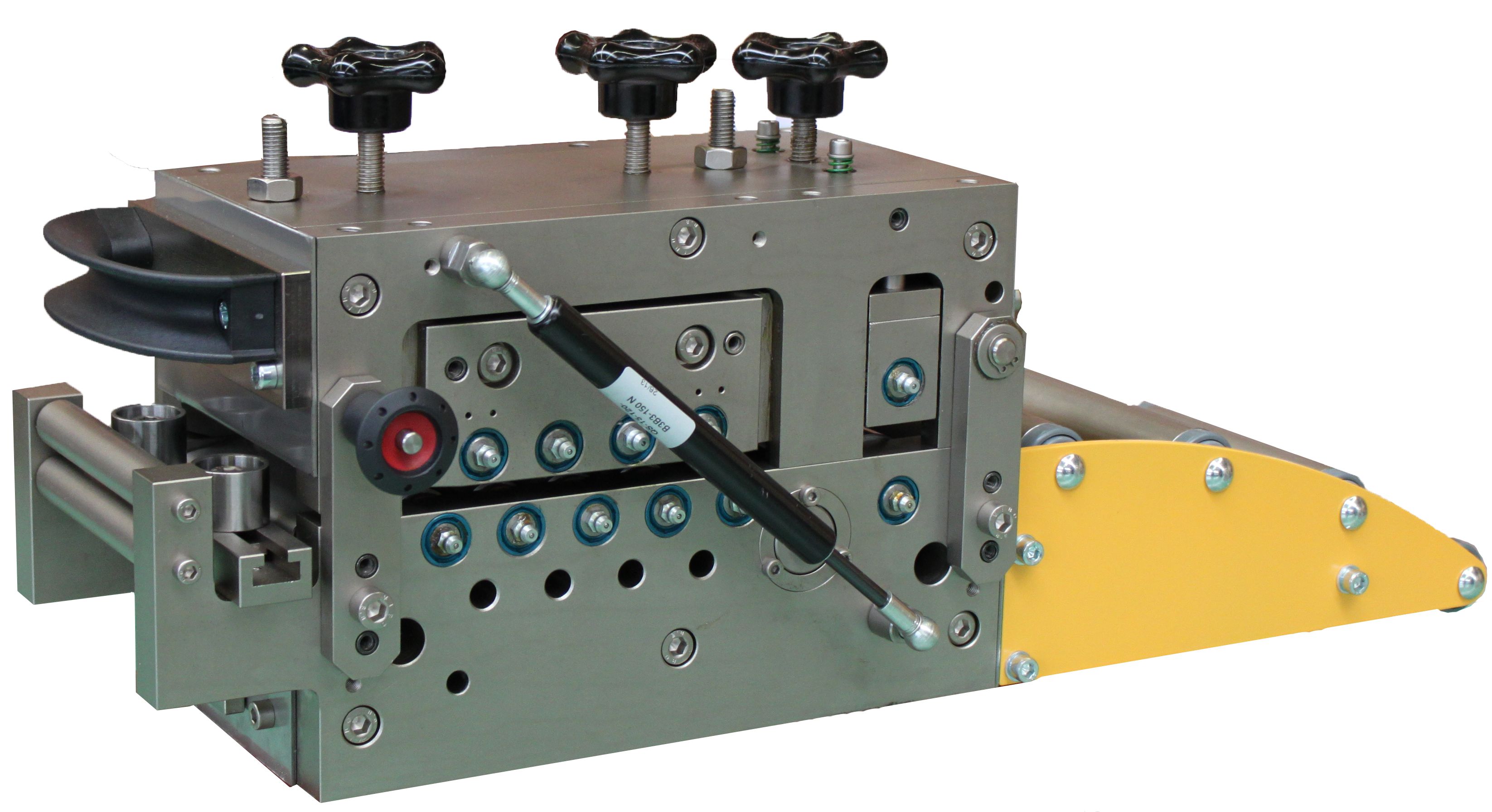

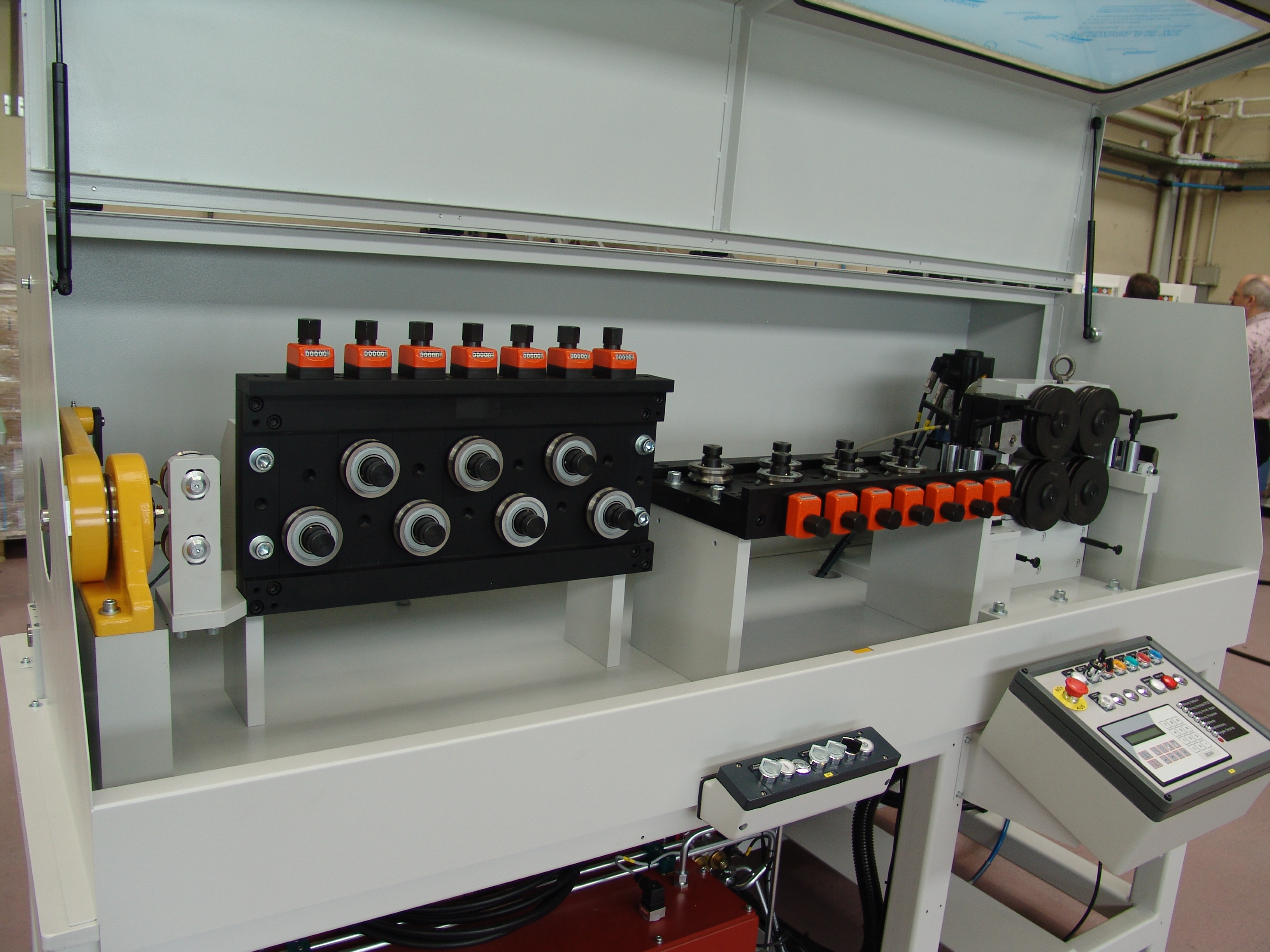

19-roller precision straightener

- Bank adjustment of the upper straightening rollers

- Multiple support rollers for all lower and upper straightening rollers

- All straightening rollers are powered

- Powered by two separate hydraulic motors

- Lower roller unit can be extracted with drawer unit

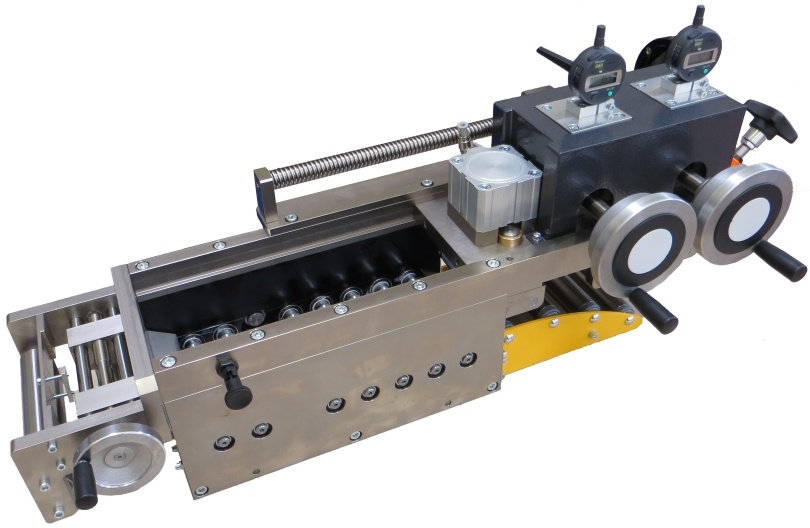

9-roller precision straightener

- Bank adjustment of the upper straightening rollers

- All lower rollers are powered

- Top of straightener extendible with spindle and handwheel

7-roller and 11-roller straightener

- Individually adjustable upper rollers

- All lower straightening rollers are powered

- Pneumatic cylinders open up top of straightener

Options

We would be more than happy to assist you and help make your specific implementation requests a reality. Simply ask one of our specialists. We can meet the following requirements, among others:

- Motorised height adjustment of straightening rollers with programme management

- Strip infeed guides and strip transfer tables

- Surface and hardening treatment of straightening rollers

- Top of straightener is openable

- Strip loop control

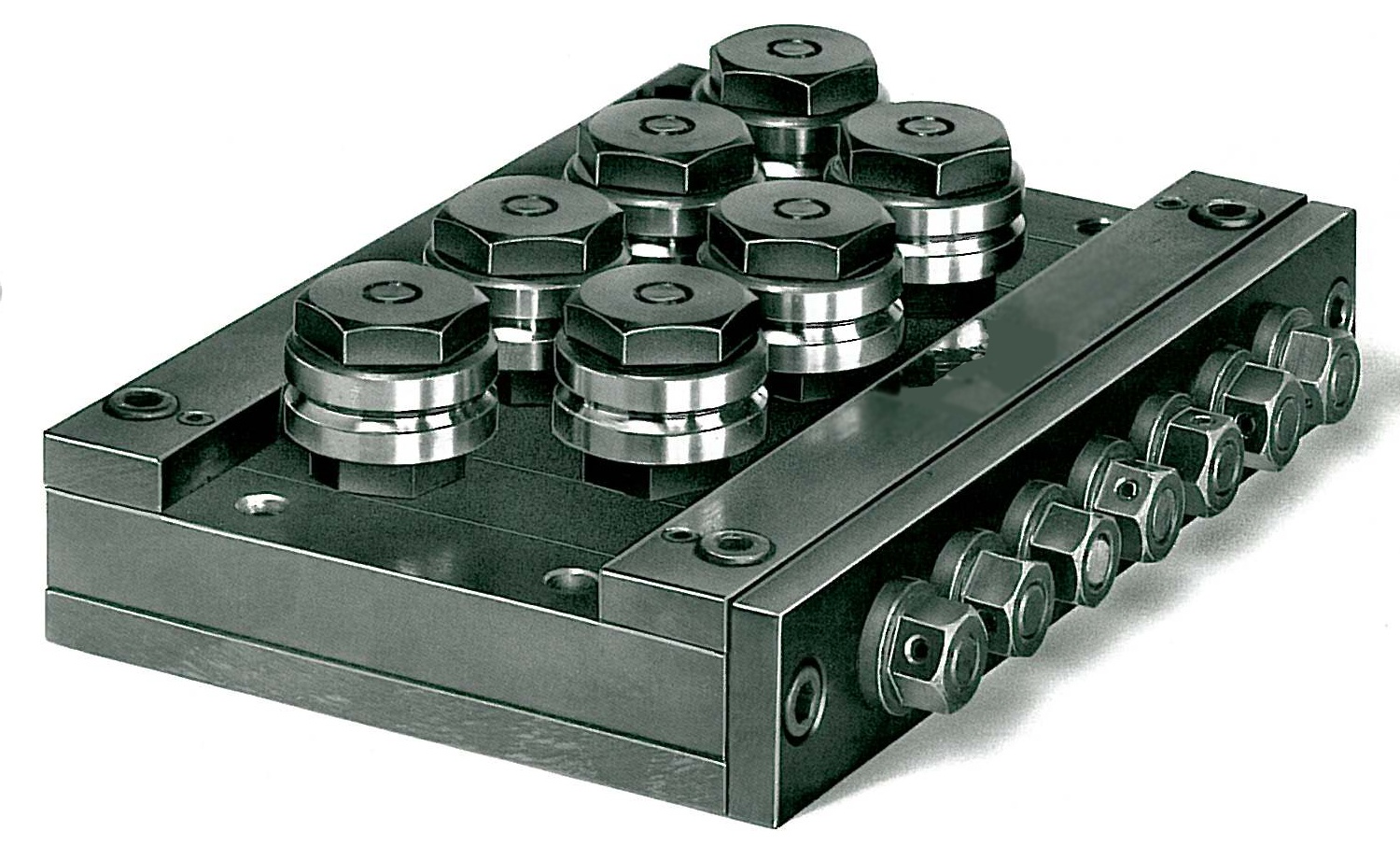

Part straighteners

| Number of straightening rollers | 17 / 23 |

| Straightening roller Ø | 6 – 30 mm |

| Thickness range | 0,05 – 6 mm |

| Passage width | 85 – 650 mm |

Functions (technical details)

- Multiple support rollers for all lower and upper straightening rollers

- All straightening rollers are powered

- Variable speed control

- Digital straightening depth display

Options

We would be more than happy to assist you and help make your specific implementation requests a reality. Simply ask one of our specialists. We can meet the following requirements, among others:

- Surface and hardening treatment of straightening rollers

- Electric transport conveyor belt and straightener infeed

- Conveyor belt or chute at straightener outfeed

- Infeed and lateral guides for strip application

- Conversion options for conveyor belt composition

Wire straighteners

| Number of straightening rollers | 5 / 7 |

| Straightening rollers Ø | 4 – 80 mm |

| Diameter range | < 15 mm |

Functions (technical details)

- Horizontal and vertical straightening device

- Quick change system for straightening rollers

- Metric counter display for straightening roller infeed

Options

We would be more than happy to assist you and help make your specific implementation requests a reality. Simply ask one of our specialists. We can meet the following requirements, among others:

- Radius puncture to match wire diameter or rectangular puncture for diameter range

- Manual wire infeed element

- Pre-straightening devices

- Roller guides

- Servo drive system

- Servo-oriented straightening plates for easier conversion to various wire diameters

+41 32 644 35 35

+41 32 644 35 35